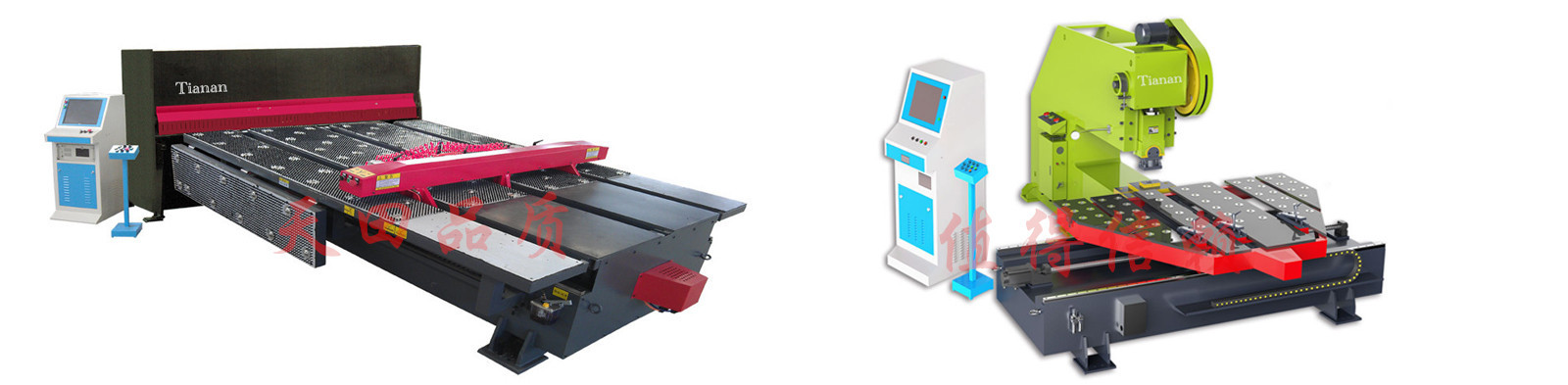

CNC punch

添加时间:2018-04-06

CNC punch press

CNC punch is the abbreviation of digital control punch, it is a kind of automatic machine tool with programmed control system. The control system can logically process programs that have control codes or other symbolic instructions and decode them so that the punch moves and processes the parts.

CNC punch function:

CNC punching machine can be used for all kinds of sheet metal parts processing, can automatically complete a variety of complex groove and the shallow stretch forming, (automatic processing according to the requirement of different size and pitch of the different shape of hole, also can use small die in step blunt blunt big round hole, square hole, waist type hole and various shapes of curve contour, also can undertake special craft processing, such as blinds, shallow drawing, sink hole, hole flanging, reinforcement, stamping, etc.). Through a simple mold combination, compared with the traditional stamping, save a lot of mold fee, you can use the low cost and short cycle processing and small batch, the diversification of products, has a larger scope and machining ability, to adapt to the change of market and products in a timely manner.

Safe operation procedure

CNC punch workers must learn to master the structure and performance of the equipment, be familiar with operating procedures and obtain operating permits to operate independently.

The safety protection and control device on the equipment shall not be removed arbitrarily.

Check whether the transmission, connection, lubrication and other parts of the CNC punching machine are normal, and the fixing screws must be firm and not movable.

The CNC punch shall operate for 2-3 minutes before work, check the flexibility of the control device such as the foot brake, and confirm that it can be used after normal, and shall not be operated with disease.

The mould should be firm, the upper and lower mould is correct, the position is correct, the machine is carried by hand to test the machine (empty car), to ensure that the mould is in good condition.

Before driving, pay attention to lubrication and remove all floating objects from the bed.

In the operation or operation of the CNC punching machine, the operator should stand properly, and the hand and head should be kept at a certain distance from the punch press, and always pay attention to the action of the punch, which is strictly forbidden to chat with others.

Stop at the end of the work, cut off the power, wipe the machine, and tidy up the environment.

Precautions for use of CNC punch.

Description of matters needing attention.

1 correct use of the industrial control machine shall not be free of power, forced shutdown.

During processing, the industrial control machine shall not run additional procedures.

Proper use of the encrypted dog shall not be hot to plug the encrypted dog.

3. Correct configuration parameters should not be changed arbitrarily and must be matched with each other.

4 the virus ensures that external input to industrial control files does not violate the malicious program.

Common problems and solutions are used for CNC punch.

The serial number problem solution.

1. The punch press is still pressed continuously.

2. Whether punch and clutch electromagnet are stuck.

2. Increase the pulse width of the sync signal 2.

3. Each hole is punched twice in a continuous stamping step 1. Improve the automatic processing speed and acceleration.

2. Reduce the distance to the appropriate distance, and the long distance will automatically stop the punch and wait for the end of movement.

4

CNC punch maintenance:

The service life of CNC punching machine has a great relationship with maintenance and maintenance. The maintenance and maintenance methods are introduced as follows:

1. The CNC punching machine shall be operated by specially trained personnel and maintained by special personnel.

2. The main movement of the CNC punch should be well lubricated. For the vice of the screw and the roller guide, if the lubricating grease is applied, the lubricating oil shall be added one or two times per week. If use of artificial dispersing lubricating oil, then each shift shall be turned on to respond to the main movement of the right amount of 20 mechanical lubricating oil. All rolling bearing parts should be filled with calcium lubricating grease, which should be added or replaced for 6 to 12 months.

3. If the power grid fluctuates frequently beyond the required range, or the noise is large, a 1.5kw computer-specific anti-interference ac stabilized power supply shall be configured.

4. As the control system often works in the vibration environment, it is necessary to check the fasteners, circuit connectors and ground bolts regularly to keep the connection firm. Keep the system clean and clean regularly.

5. It is not allowed to connect the ac/dc power supply used within the nc system to other electrical appliances.

6, control cabinet should be reliable grounding, grounding resistance Ω ﹤ 4.

7. 1-2 months to clean and dust the dust cover of the industrial control machine, and the power supply must be cut off before operation.

8. 1-2 months to clean the electric box, the components and the housing in the cabinet, and the power must be cut off before operation.

9. Check the fastening bolt of the connection part of the equipment regularly, depending on the equipment usage, 2 ~ 3 times per month.

在线客服1号

在线客服1号